产品介绍及网络组建

Product Brief & Network Setup

压装示意图

Press-Fitting Schematic Diagram

伺服压机按照设定的参数精确压装,实时监测反馈压装尺寸,保证最终装配精度。同时可以设定压力和位移质量判定区域,在线检测确保产品压装100% 合格。

The servo press performs precise pressing according to theset press-in depth, monitors and feeds back the pressingdimensions in real time to ensure the final assembly accura-cy. Meanwhile, it can set pressure and displacement qualityjudgment zones, and conduct online inspection to guaran-tee 100% qualification of the pressed products.

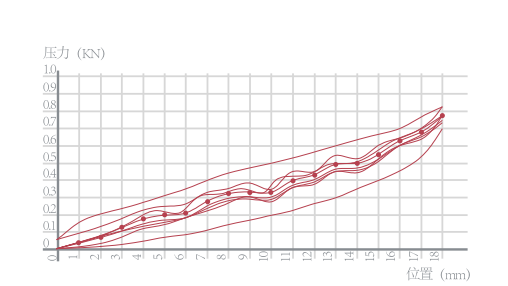

包络线示意图

Envelope Curve Schematic Diagram

自主研发控制系统软件,涵盖运动控制规划、曲线自动采集处理、包络线手动补偿绘制、曲线评估等功能,实现压力及位置分段精确控制。

Independently developed control system software coversfunctions such as motion control planning, automatic curvecollection and processing, manual envelope curve compen-sation and drawing, and curve evaluation, enabling precisesegmented control of pressure and position.

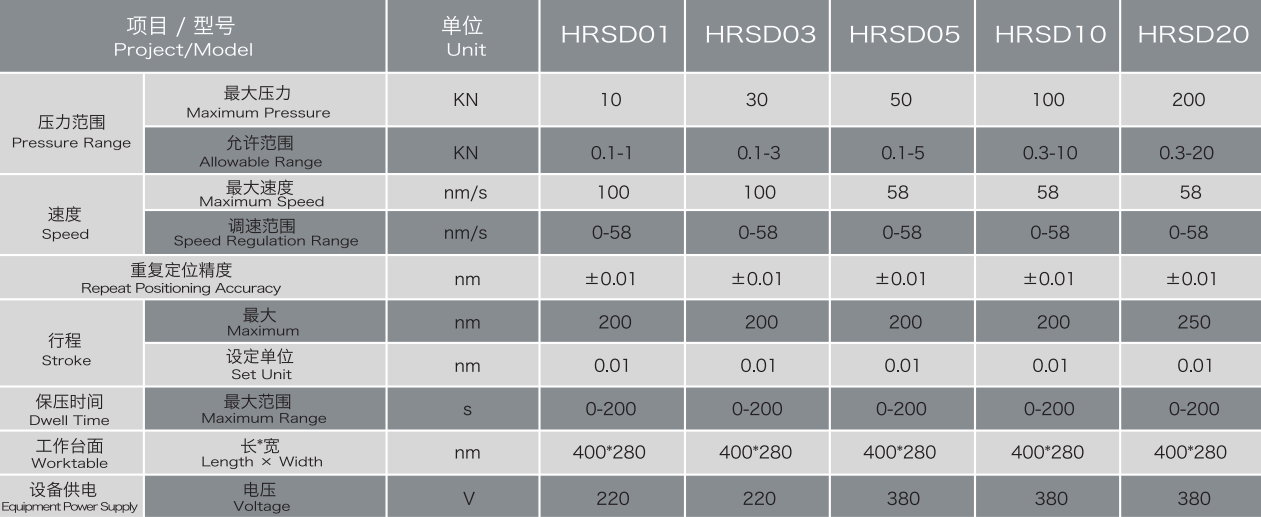

智能伺服压机选型

Intelligent Servo Press Selection

操作系统功能介绍

Introduction to Operating System Functions

Touch Screen Manual Control Interface

Select and set parameters according to usage requirements, track pressure andposition in real time during the pressing process, and support a multi-purposeparameter setting mode.

Function Introduction of Intelligent Servo Press

Touch Screen Main Interface

1.Real-time track and display pressing information, and judge OK/NG.

2.Envelope curve status tracking and display.

扫描二维码分享到微信

+86 13122838255