产品中心PRODUCT

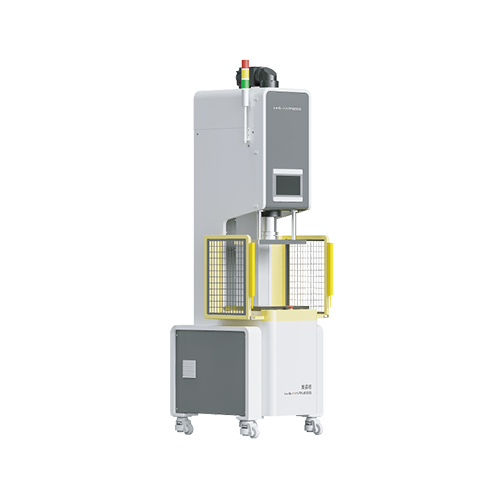

台式智能伺服压机

台式机型小巧轻便,适合桌面作业预留外接气缸单元3组The desktop model is compact and lightweight,suitable for desktop operations.3 sets of external cylinder units are reserved.

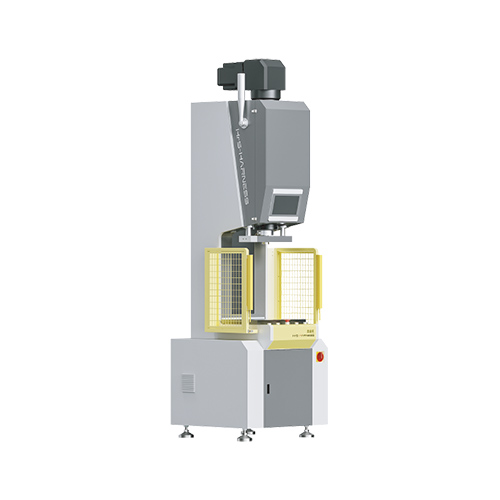

3T智能伺服压机

预留外接I/O点16组系统无需二次开发,可升级自动线模式外部预留自动线对接端口可根据用户需要配备扫码追溯以及MAS 系统16 sets of reserved extemal I/O points.No secondary development required for the system,which can be upgraded to automatic line mode.Exteral reserved ports for automatic line connection.Optional code scanning traceability and MAS systemaccording to user needs.

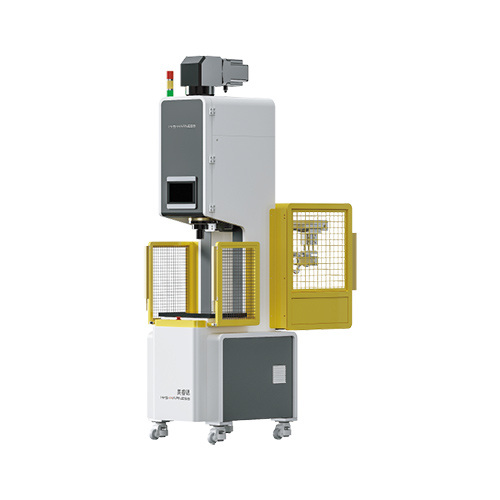

5T智能伺服压机

预留外接I/O点16组系统无需二次开发,可升级自动线模式外部预留自动线对接端口可根据用户需要配备扫码追溯以及MAS 系统16 sets of reserved extemal I/O points.No secondary development required for the system,which can be upgraded to automatic line mode.Exteral reserved ports for automatic line connection.Optional code scanning traceability and MAS systemaccording to user needs.

10T智能伺服压机

预留外接I/O点16组系统无需二次开发,可升级自动线模式外部预留自动线对接端口可根据用户需要配备扫码追溯以及MAS 系统16 sets of reserved extemal I/O points.No secondary development required for the system,which can be upgraded to automatic line mode.Exteral reserved ports for automatic line connection.Optional code scanning traceability and MAS systemaccording to user needs.

5T智能伺服压机多工位基础款

工作台配备多工位分割器外部预留自动线对接端口可根据用户需要配备扫码追溯以及MAS 系统The workbench is equipped with a multi-stationindexer.Extemal reserved ports for automatic line connection.Optional code scanning traceability and MAS systemaccording to user needs.

5T智能伺服压机自动上料款

配件机械手自动上料,根据配件结构配置料盘外部预留自动线对接端口可根据用户需要配备扫码追溯以及MAS 系统Automatic feeding via accessory manipulator, traysare configured according to the accessory structure.Extemal reserved ports for automatic line connection.Optional code scanning traceability and MAS systemaccording to user needs.

自动化组装生产线

根据产品装配工艺任意组合产线系统及设备无需二次开发,按标准机型快速组建柔性生产线可根据用户需要配备扫码追溯以及MAS 系统Arbitrarily combine production lines according to product assembly processesNo secondary development required for the system and equipment, enablingrapid construiction of flexible production lines with standard models.Optional code scanning traceability and MAS system according to user needs

四柱伺服压机

根据产品装配工艺任意组合产线系统及设备无需二次开发,按标准机型快速组建柔性生产线可根据用户需要配备扫码追溯以及MAS 系统Arbitrarily combine production lines according to product assemblyprocesses.No secondary development required for the system and equipment,enabling rapid construction of flexible production lines with standardmodels.Optional code scanning traceability and MAS system according touser needs.

核心优势 Core advantages

智能化生产 Intelligent Production

多元化控制界面,压装方式灵活配置。

Diversified control interfaces and flexible configuration of press-fitting methods.

数据追溯 Data Traceability

实时上传位移及压力信息,操作系统可兼容MAS系统。

Real-time upload of displacement and pressure information, with the operating system compatible with MAS systems.

大容量数据存储 Large-Capacity Data Storage

生产数据同步上传,供生产管理单位实时查看。

Production data is synchronously uploaded for real-time viewing by production management units.

精度精密 High Precision

位移、压力双重监控,包络线提供灵活算法。

Dual monitoring of displacement and pressure, with flexible algorithms provided by envelope curves.

自研控制芯片 Self-Developed Control Chip

控制系统满足多种使用场景。

The control system meets various application scenarios.

关于我们ABOUT US

昊睿锶(上海)机电科技有限公司,坐落于上海上圣东尼高科产业园,源于意大利精

湛的工艺技术多年来深耕精密装配行业。自主研发控制系统及软件,涵盖运动控制规

划,曲线采集处理,曲线绘制,曲线评估,链入MES生产管理系统等功能。

Haoruisi (Shanghai) Electromechanical Technology Co., Ltd., Based in Shanghai Shang Sheng Toni

High-Tech Industrial Park, WRST inherits Italian exquisite craftsmanship and has deep roots in the

precision assembly industry for years. Independently developed control systems & software

cover motion control planning, curve acquisition/processing/drawing/evaluation, and MES integration.

自主研发

控制系统及软件

Independently developed

control system and software

管理生产数据

满足高精度要求

Managing production data meet

high precision requirements

智能制造

整体解决方案

Intelligent manufacturing

overall solution

地址ADDRESS

Address

COPYRIGHT (©) 2025 昊锐锶(上海)机电科技有限公司. 沪ICP备2025152988号

扫描二维码分享到微信